Creating tires is no walk in the park. It’s actually a pretty intricate process that involves some serious knowledge of materials science, engineering know-how, and precision skills. Surprisingly enough, though, not many folks out there truly grasp just how meticulous it all really is!

This article will shed some light on this fascinating journey from raw materials to ready-to-roll rubber wonders we call tires. Let’s dive right into the captivating world of tire manufacturing together!

Material Preparation

The very first step in making those awesome tires we all rely on is getting the materials ready. Sure, rubber takes center stage here, but there’s more to this recipe than meets the eye. We’re talking about carbon black, sulfur, and even some fabric thrown into the mix.

Big bundles of raw rubber roll up at the tire factory like VIP guests arriving at a fancy party. From there, they head straight to that mill where things start heating up! The heat softens everything up just right as our star ingredient gets mixed with other goodies aimed at boosting its performance.

This miracle mixture wouldn’t be complete without a little something called “viscous rubber additive.” Its special powers? Well, imagine your tire being flexible while standing strong against everyday wear and tear. This magical additive makes sure our favorite wheels last longer!

Building the Tire

Let’s move on to the next phase of making a tire – it’s all about putting this together! Do you know what helps us get the job done? A mighty machine called the tire drum. Think of it as our trusty sidekick in assembling all those different parts that come into play.

We start by laying down an inner liner. That part is essential for keeping the air right where it belongs inside your soon-to-be rad rubber circle. Then comes some fabric and steel belt time. They add strength and stability like nobody’s business!

Tread and sidewall compounds make their grand entrance. The tread gives you a grip on any road surface. Meanwhile, those sidewalls keep things stable when taking tight turns or quick maneuvers.

Every step is taken with meticulous care so each tire meets precise specifications! We’re talking about top-notch quality, ensuring optimal performance every single time our tires hit the pavement.

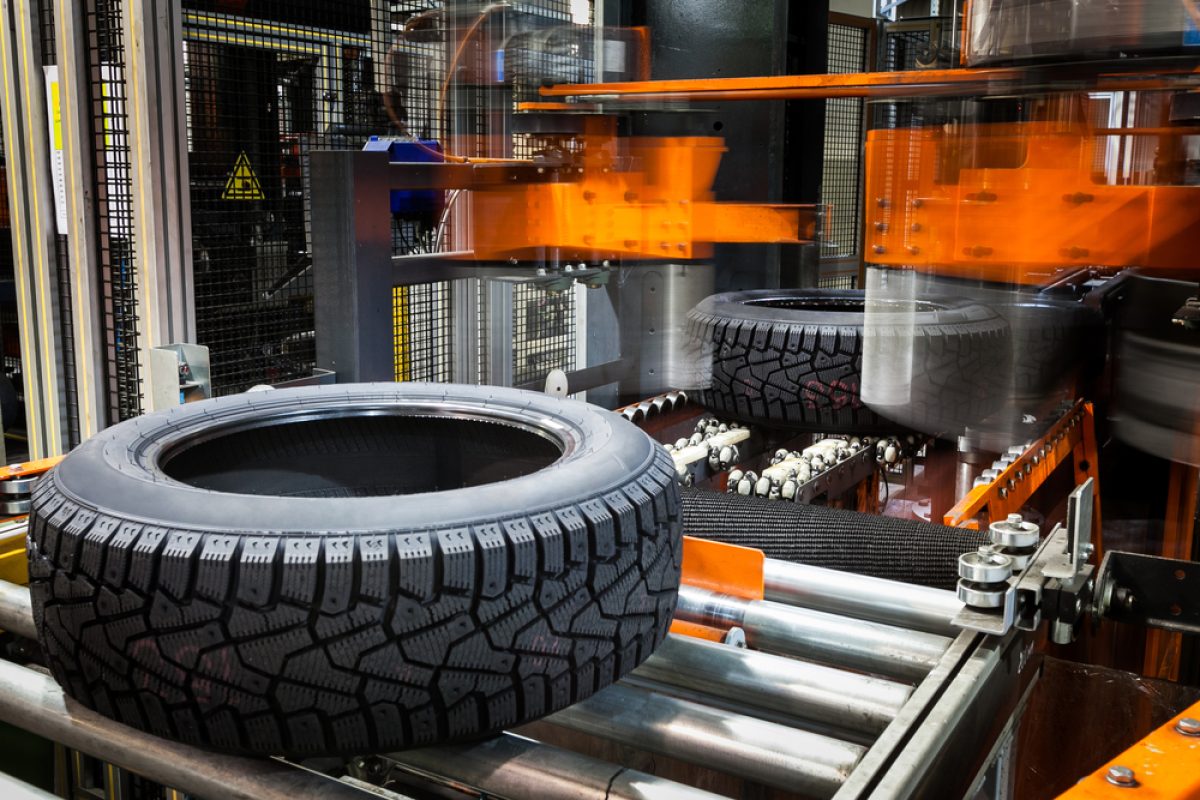

Curing and Inspection

We’ve reached the home stretch of tire manufacturing – it’s all about that curing process now! So, once our well-built tire is ready to roll, it takes a trip to the magical land of heat and molding. Welcome to the curing press!

Inside this incredible machine, our little newborn gets treated with some serious temperature action. The high heat works wonders by triggering vulcanization. It is a fancy term for when rubber becomes strong and durable while also getting that cool tread pattern imprinted onto its surface.

Once out from their cozy heating session, these tires need an inspection like no other. Highly trained inspectors take charge using both nifty machines and their human eyes to comb through every inch looking for any flaws or imperfections.

They’re on top of balance checks! They have to make sure those wheels are as smooth. And let’s not forget uniformity, either – every single one must meet strict standards before they hit retailers’ shelves.

Only after passing such rigorous tests do these amazing tires earn themselves a ticket straight into vehicles everywhere. They are ready for whatever road adventures lie ahead!

Conclusion

To sum it all up, tire manufacturing is a sophisticated dance between art and science.

- The meticulous preparation of materials.

- The careful assembly process.

- The crucial curing phase followed by a thorough inspection.

Every step plays a vital role in creating those trusty tires that safely take us wherever we need to go!

2018 ·

2018 ·

Leave a Reply