What Is Acrylic and What Does It Do?

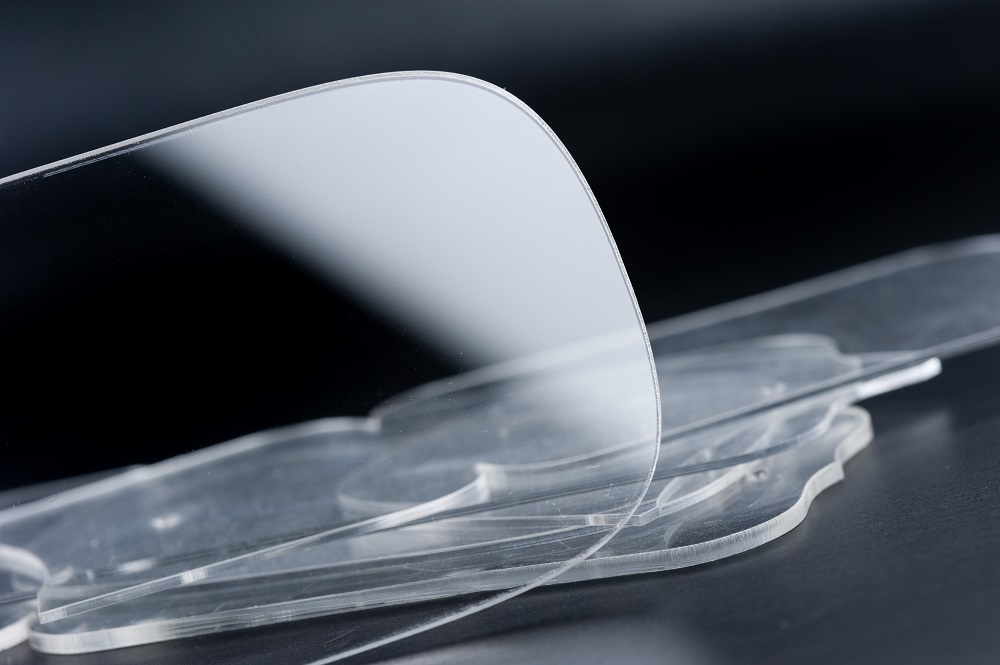

Acrylic is a transparent thermoplastic homopolymer known as “plexiglass” by the trade name. It is a polycarbonate-like material that may be used as an impact-resistant alternative to glass (particularly when the high impact strength of PC isn’t required). It was first produced in 1928 and debuted on the market five years later. It is regarded as one of the most transparent plastics available. In the Second World War, acrylic was used for submarine periscopes as well as aeroplane windows, turrets, and canopies. Airmen who were wounded by broken acrylic shards fared considerably better than those who had injuries from shattered glass.

Acrylic is nowadays utilised in a wide range of applications, many of which take advantage of its natural transparency and the impact resistance provided by various types. Acrylic nails, paint, security barriers, medical devices, LCD displays, and furniture are just a few examples of its many applications. It’s also commonly utilized for windows, tanks, and enclosures surrounding exhibits due to its clarity.

Why is acrylic utilised so often?

Acrylic is a wonderful material for applications that need transparency and resistance to high impact. Comparing clear plastics, Acrylic is much more scratch-resistant. It’s a less heavy and more durable option than glass, as well as a cost-effective alternative to polycarbonate in situations where strength isn’t particularly important. The material vaporizes when hit with concentrated laser energy, making it possible to cut into extremely tiny forms using laser cutting technology. Acrylic is a popular choice for 3D printing because of its brittle failure and poor strength. Instead, we generally utilize PC or PETG. Despite the fact that PC and PETG aren’t as transparent as Acrylic, they are typically “clear enough.” Acrylic is the clear choice if crystal clarity is critical. We’ve machined acrylic on the CNC and hand-formed it as well. The components must generally be polished after machining to remove tool impressions and restore optical clarity. A few examples include the following:

- as a lens

- as a general replacement for glass

- display products

- fashion accessories

What Are The Different Types of Acrylic?

Acrylic plastic, the material of choice for many aquariums, was first produced in 1843 by adding formaldehyde to a solution of polyethene. In 1933, German chemist Otto Rohm applied for the trade name “plexiglass,” which he had created. It’s produced by a large number of businesses, each with its own manufacturing process and proprietary recipe. Trade names include well-known variations like Perspex, Plexiglas® by ELF Atochem or Lucite® by DuPont.

How is Acrylic made?

Acrylic plastic polymers are produced by combining a monomer, such as methyl methacrylate, with a catalyst. An organic peroxide is a typical catalyst. The catalyst starts the reaction and participates in it to keep it going, but does not become part of the final polymer.

Acrylic plastic sheets are manufactured by bulk polymerization. The monomer and catalyst are mixed in a mould where the reaction occurs, after which the mixture is poured into the mould. Bulk polymerization may be done in two ways: batch cell or continuous operation. The most popular type is the batch cell, which can make acrylic sheets in thicknesses ranging from 0.06 to 6 inches (0.16-15 cm) and widths ranging from 3 feet up to several hundred feet. Rods and tubes may also be manufactured using this technique. The continuous technique is more efficient and less time-consuming. It’s used to make thinner sheets of a lesser width and thickness than those made with the batch cell method.

2018 ·

2018 ·

Leave a Reply